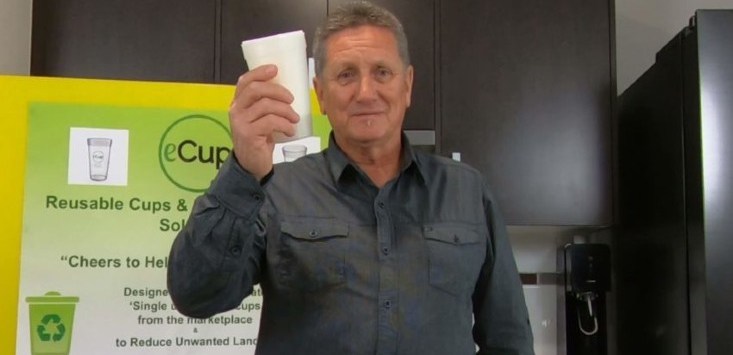

eCup founder and creative director John Maule.

South Australian business eCup was set to begin manufacturing its reusable cups in China late last year.

But the economic impact of the bushfires and the coronavirus-induced lockdown brought these plans to a halt, says founder and creative director John Maule.

Some eight months on, Maule has launched a Kickstarter campaign to raise funds to have the interactive cups produced in Adelaide and help drive a circular economy in the process.

Made from polypropylene, the eCup was designed as a replacement for single-use plastic cups at events, in a bid to reduce the waste and costs associated with their collection.

Maule says the cost of producing the mould needed to manufacture the cups in Australia was about $160,000 prior to the pandemic compared with $15,000 in China.

However, he said a weaker Australian dollar, and desire to stimulate the local economy following the biggest national unemployment crises this century, has driven down the price for a locally made mould to about one-third of its previous estimate.

“The figures were nowhere near what they are now … and people wanted to work, wanted to help and I was actually astounded and very relieved,” Maule says.

“So now we have a system whereby we can produce our moulds in Adelaide, our products in Adelaide, and it’s all localised.”

The decision to produce locally comes as the Australian government’s National COVID-19 Commission Advisory Board examines a national strategy to drive different manufacturing sectors in each state.

Australian Industrial Transformation Institute director John Spoehr says that eCup was among a wave of businesses looking to revive manufacturing in the state.

“I certainly am more aware now — more than in my 30 years of following the manufacturing debate — that rather than the attention being on outsourcing and manufacturing through global supply chains, the focus is very squarely on whether or not it’s possible to manufacture locally,” Spoehr says.

“I can’t remember having such a robust debate around the importance of sovereign manufacturing as we’re having at the moment.

“We’re asking the question: ‘What should we be producing in Australia as a matter of course to de-risk the Australian environment against the sorts of shortages that we’ve experienced in recent times?’”

“COVID-19 has exposed lots of vulnerabilities in our supply chains. Particularly our dependence on imports and a whole range of goods … as we have become dependant on China and other nations,” Spoehr adds.

Spoehr says South Australia’s manufacturing leaders were considering ways to drive more local manufacturing business off the back of defence and space projects.

“Our big defence manufacturing projects have been identified as a major driver of building more robust manufacturing supply chains in Australia, by getting a wide range of small to medium enterprises in the future frigate and submarine projects,” Spoehr notes.

“It’s easy to forget South Australia is still a strong manufacturing state.

“With the close of the automotive industry, there are still 60,000 to 70,000 manufacturing jobs in South Australia — and there will be substantial shipbuilding over the next few years, which is going to create 5000 plus jobs.

“So the challenge for us is leveraging that investment in shipbuilding for the growth of manufacturing in other sectors.”

Maule says, as part of the circular economy, the eCup will help create jobs beyond the manufacturing industry, with the company looking to employ about 15 people in the first year including in marketing and events positions.

“There are two means to eCup: one is to buy and one is to hire,” Maule explains.

“So you can buy a cup at the venue or you can hire it for an event. If you hire it for an event, you create a circular economy.

“Once we pick it up from you we take it back to the warehouse, we put it back in the washer, it’s sanitised and untouched by hand and it goes back into a plastic sleeve into the box. So it’s stored and never reaches a landfill.

“If you buy it, people will pay a deposit at the bar when they get their cup — very similar to what you do with the wine shows. You buy your glass and you keep it and take it up to the bar when they get a fresh drink.

“If it’s taken home … people can keep on using it, take it camping and do whatever you like with it,” Maule adds.

Maule says there would be two styles of cup available — the Freddie and the Mary-Lou — with individual in-mould labelling.

He explains the eCup took its name from its ability to link with digital platforms.

“We’ve created and developed a cross-media platform which … you can actually print or scan any photo on that in-mould labelling and that will direct it to a website,” Maule says.

“For example, if you have your favourite sports player, say for the Crows or Port Adelaide, and his face is on there it’ll give you all his stats on your screen.

“We’ve put technology into the cup.”

He says he hopes to raise $122,000 through the Kickstarter campaign, which would be used to pay for the moulds, with an aim to release eCup in time for summer.

This article was first published by The Lead.

COMMENTS

SmartCompany is committed to hosting lively discussions. Help us keep the conversation useful, interesting and welcoming. We aim to publish comments quickly in the interest of promoting robust conversation, but we’re a small team and we deploy filters to protect against legal risk. Occasionally your comment may be held up while it is being reviewed, but we’re working as fast as we can to keep the conversation rolling.

The SmartCompany comment section is members-only content. Please subscribe to leave a comment.

The SmartCompany comment section is members-only content. Please login to leave a comment.